The top is a 1 3/4" thick solid core door, and it's pretty easy to tell the difference. An average hollow core door weighs maybe 15 - 20 pounds, while a solid core door weighs 80 - 90 lbs. Some doors are made out of actual lumber inside, while the cheaper ones are a mixture of wood fibers and glue that is HEAVILY compressed together inside the outer lumber veneers. I got the latter, seeing as it was impossible to find the former, and it seems to have worked out quite well. In addition, it only cost me $55 at Home Depot, which is NOT the lowest price retailer you can find.

I had wanted to use wood 4x4's for the bench legs, but I could not figure out how to hold them to the top with rock solid stability, so I got the following steel table legs which also had knock-outs for electrical outlets.

http://www.globalindustrial.com/p/work-benches/components/legs-shelves/adjustable-height-27-7-8-to-35-3-8-leg-30-benches-2

After I cut the door to a 32" x 60" size, I finished it with some stain and put about 5 coats of satin polyurethane varnish over the top. I did NOT take special care trying to produce a streak-free finish! The reason for this is that after the varnish dried, I wet sanded the top with grade 220 Wetordry sandpaper and boiled linseed oil. It's messy, but the result is a dead smooth finish, and boiled linseed oil cures up just like varnish, except it takes longer. The advantage to this is that if the top gets dirty or scratched, you can just go over it again with more 220 grit and boiled linseed oil to renew the surface.

I used slotted steel angle to stiffen up the top on the underside, and also to provide a way to put on the side boards without any hardware showing. Shown below is a picture of the underside of the bench, and the slotted steel angle and the table legs are bolted to the top with 5/16" x 1" steel lag screws. To get the maximum strength bond between the top and the legs/angle, you need to drill holes about half the major diameter of the screw 3/4" deep in the underside of the top.

The next step is torqueing down the lag screws, and you want to do this with a torque wrench. You can figure out how many ft-lbs of torque you need by picking a torque value where the tightening force is STILL CLEALY INCREASING. What you are trying to avoid is torqueing the screws too hard, so that the holding force starts to go back down because the screw threads have started to strip the wood out of the holes! In my case, 10 ft-lbs was the value that I selected.

The underside of the bench is shown below:

You can see the lag screws holding the steel to the top, and also the electrical outlets and the Romex wiring to connect all the outlets to the wall plug.

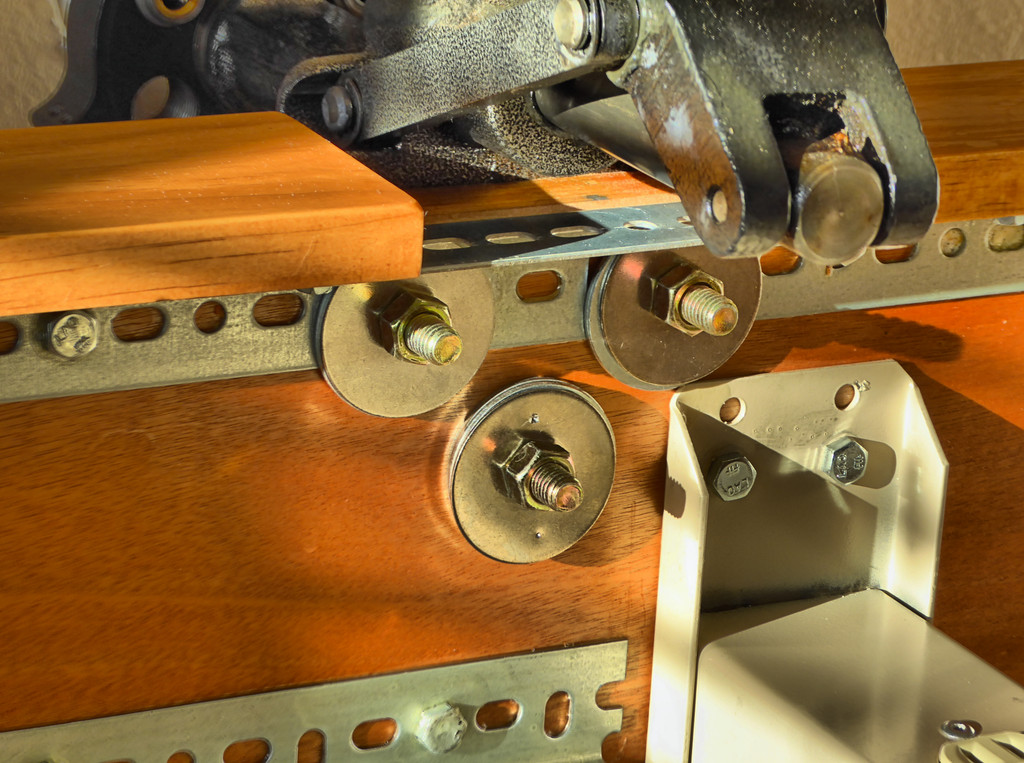

The view below is a close up of the attachment of the press to the top, and this is where you want the considerable force applied to the press to be spread out as much as possible. The two front bolts go though the slotted angle and then have large steel washers to spread out the force, and the back bolt has even heavier washers than the front ones. You know when you have tightened up the nuts enough when the force goes up VERY fast to the point that the wrench won't move any more!!

Here you can see the side lag screws holding the 1 x 4 pine sides to the steel angle, and these are #14 x 3/4" lag screws. Note that steel angle is NOT necessarily exactly a 90 degree angle, so once the steel is bolted to the top you have to use a vise grips to bend it out to a good square 90 degree angle.

The next pictures show the finished bench, and as you can see it looks like a pretty decent piece of furniture, considering how much force it has to withstand, and also how many gun chemicals and lubricants that will get spilled on it.